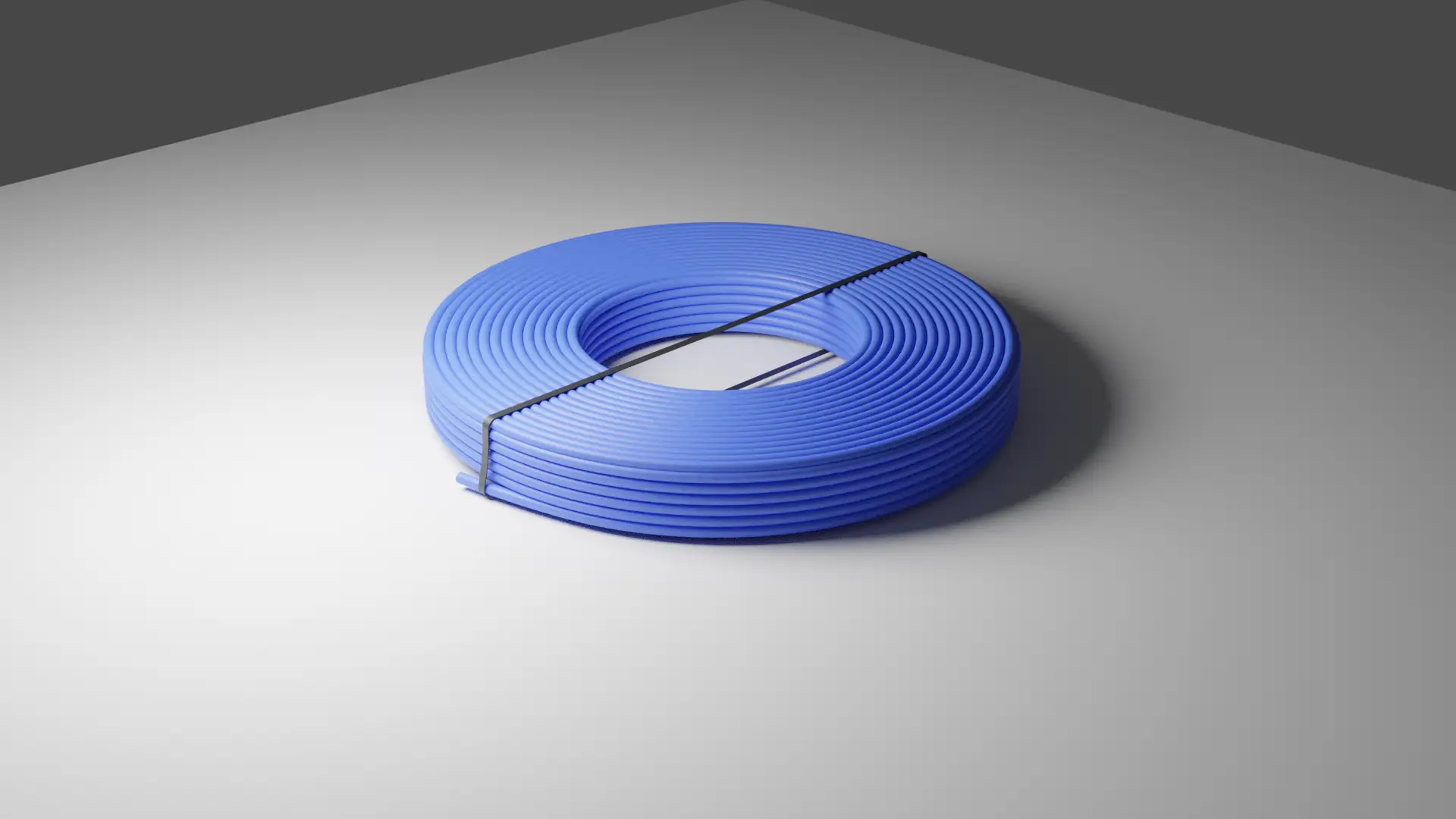

Winding of flexible products

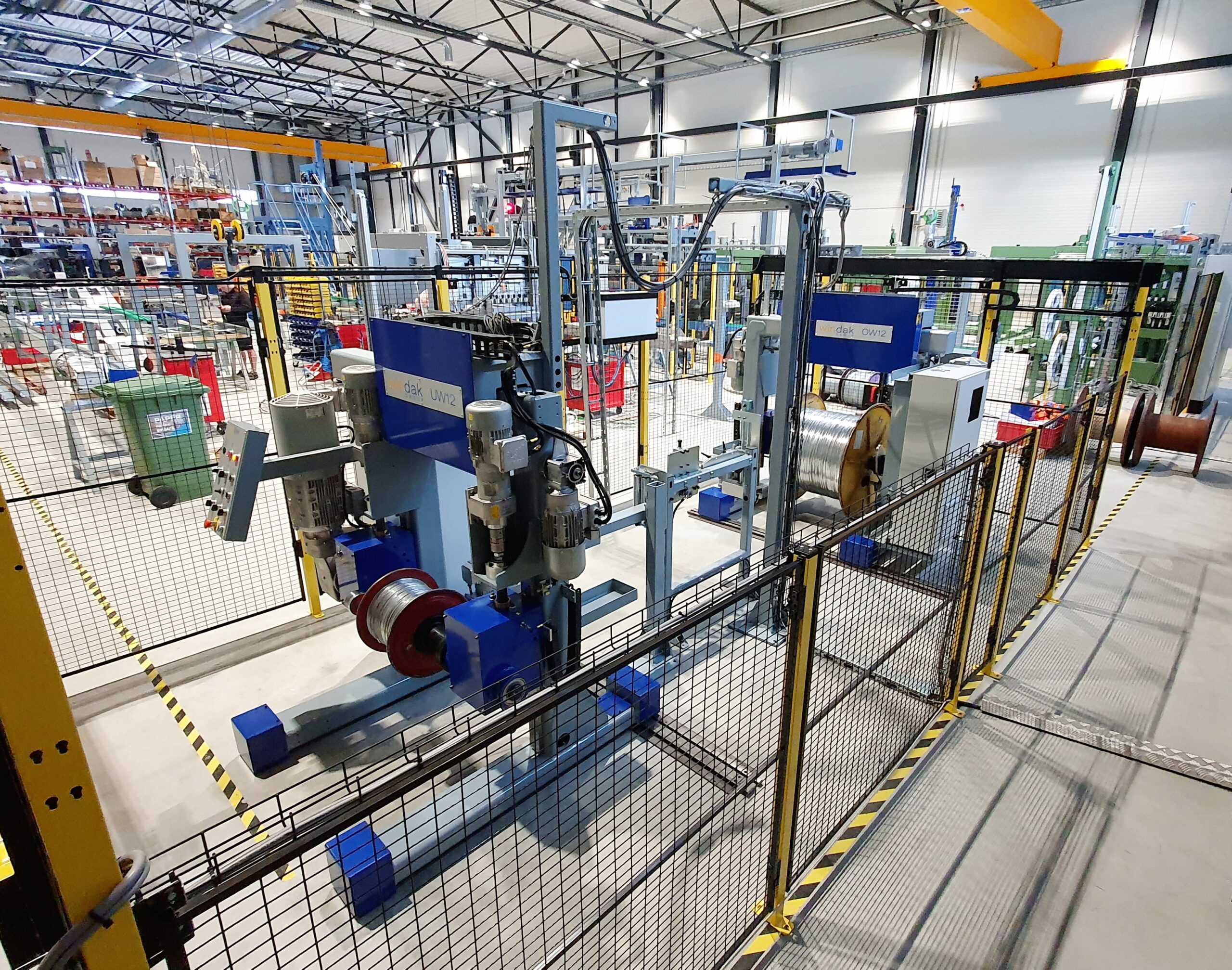

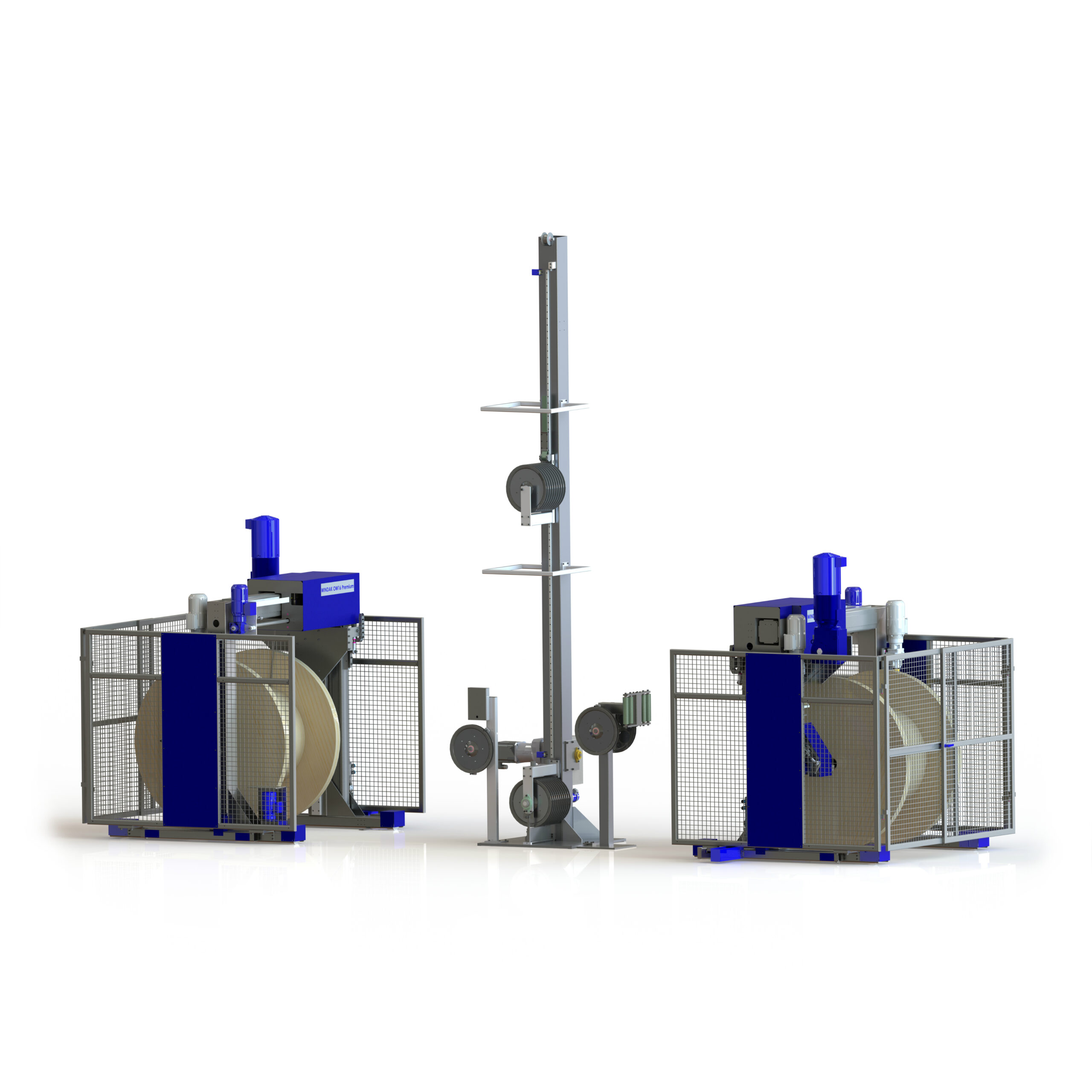

Rewind Lines – UW – OW10/12/16/22/26/30

Request the product catalogueWindak Rewind Lines are available in both tire driven and conventional drive pin designs.

The rewind line control system consists of the complete integration of the rewinding line functions, it includes a line control cabinet, an operator control panel with a 10” full color HMI, for full control of the rewinding line.

Features

- Line Speed Control: Offers speed and torque mode for both pay-off and take-up.

- Spark Tester Function: Line slows to a controlled stop when a spark fault is detected.

- Printer Function: Allows setting of printer distance calibration and initiation of print.

- One-Button Jog Feed: Simplifies product feed out from pay-off during stringing up.

- Take-Up Traverse Control: Enables setting of all parameters for precise control.

- Accurate Length Measuring: Ensures precise measurement of product length.

Available Options

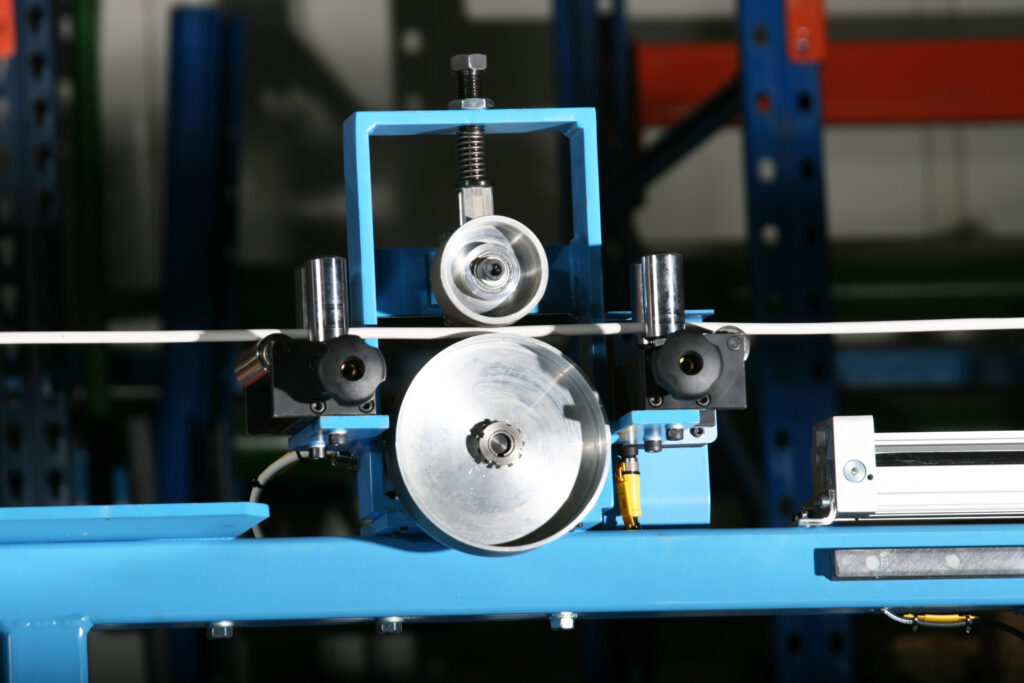

- Laying Unit: Enhances wind quality even further.

- Remote Control: Enables on-the-fly reversal point adjustment and laying quality control from a safe area, optimizing efficiency and convenience.

- Touch Screen HMI: Adds user-friendly interface for efficient control and operation.

- Low Tension Dancer: Ideal for handling sensitive products.

- Caterpillar or Tire Capstan: Designed to support the rewind of heavy cables.

- Customer Equipment Integration: Seamlessly incorporates customer-supplied equipment, such as taping units.

- Integrated Cutter and Test Equipment: Offers combined cutting and testing functionalities.

- Safety Guarding: Ensures operator safety and meets CE standards.

Specifications

| Model | Reel flange diameter (mm) | Reel flange diameter (inches) | Reel overall width (mm) | Reel overall width (inches) | Max Reel weight (ton) | Main motor AC drive size (kW) |

| UW & OW10 | 400 - 1 000 | 16 - 40 | 250 - 750 | 10 - 30 | 0.4 | 2,2 |

| UW & OW12 | 400 - 1 250 | 16 - 49 | 375 - 950 | 15 - 37 | 2.5 | 7.5 / 11 |

| UW & OW16 | 400 - 1 600 | 16 - 63 | 475 - 1 150 | 19 - 45 | 4.5 | 7.5 / 11 |

| UW & OW16T | 400 - 1 600 | 16 - 63 | 475 - 1 150 | 19 - 45 | 4.5 | 7.5 |

| UW & OW22 | 600 - 2 200 | 24 - 87 | 720 - 1 400 | 28 - 55 | 6 | 11 / 15 |

| UW & OW22T | 600 - 2 200 | 24 - 87 | 720 - 1 400 | 28 - 55 | 6 | 7.5 |

| UW & OW22DT | 600 - 2 200 | 24 - 87 | 720 - 1 400 | 28 - 55 | 8 | 2 x 7.5 |

| UW & OW26 | 800 - 2 600 | 32 - 102 | 830 - 1 730 | 33 - 68 | 8 | 11 / 15 |

| UW & OW26T | 800 - 2600 | 32 - 102 | 830 -1400 | 33 - 55 | 8 | 7.5 |

| UW & OW26DT | 800 - 2600 | 32 - 102 | 830 -1400 | 33 - 55 | 12 | 2 x 7.5 |

| UW & OW30 | 1 200 - 3 000 | 47.2 - 118 | 1 200 - 2 400 1 000 - 2 200 800 - 2 000 | 47.2 - 94.5 39,3 - 86.6 31.5 - 78.7 | 20 | 15 |

| UW & OW30DT | 1 200 - 3 000 | 47.2 - 118 | 1 200 - 2 400 1 000 - 2 200 800 - 2 000 | 47.2 - 94.5 39,3 - 86.6 31.5 - 78.7 | 20 | 2x 9.2 |

Speed and output depend on your application.

Elevate Your Operations: Exceptional

Equipment Benefits

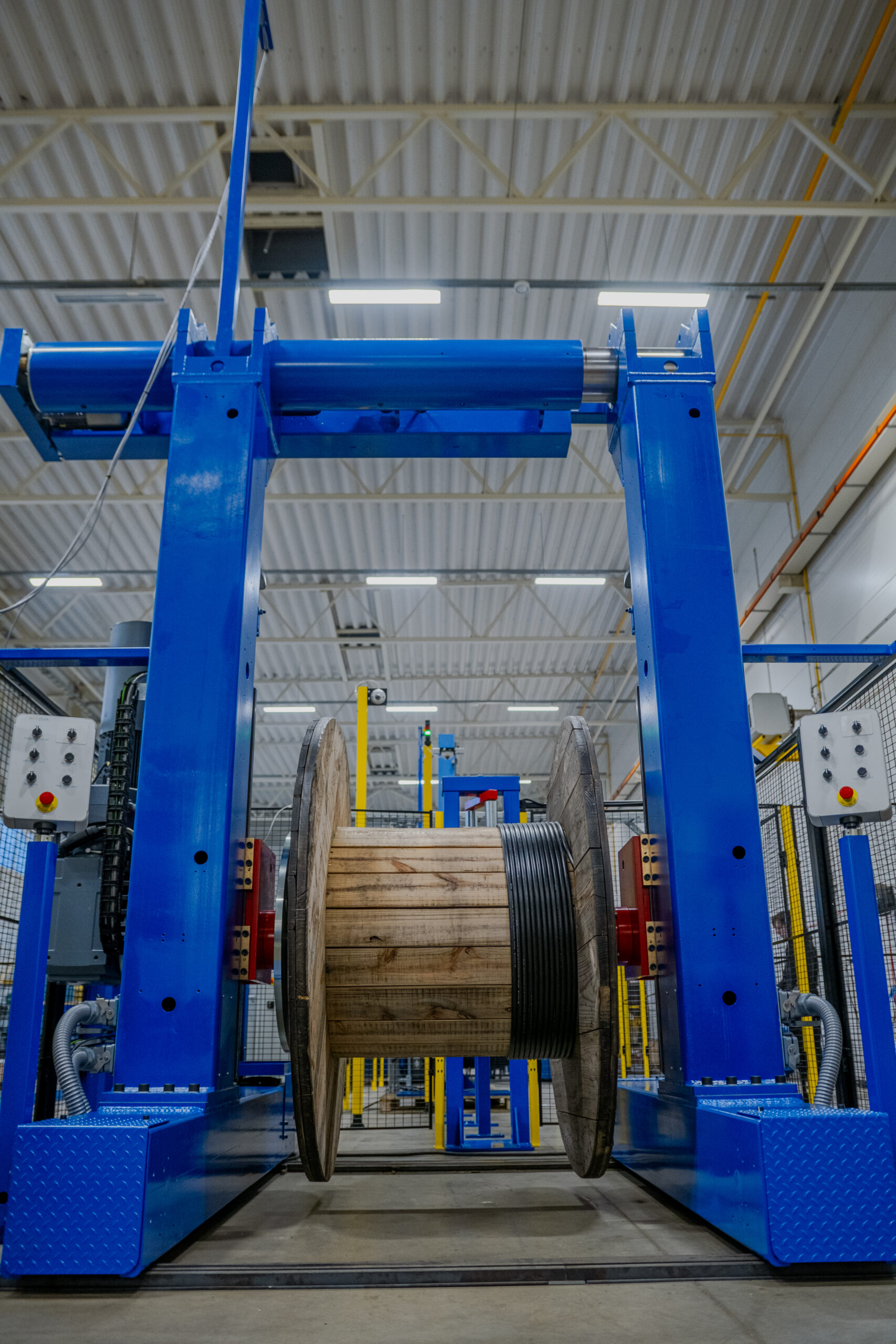

Quick and Safe Reel Changes

Features a floating design pintles for rapid and secure reel changing and setup.

Synchronized Payoff and Take-up

Features fast acceleration and deceleration to minimize cycle times.

Superior Laying Quality

Delivers outstanding laying results. Optional Safewind laying quide.

Versatile Reel Driving Options

Capable of driving the reel on the flange or using a conventional drive pin.

Speed and/or Torque Mode Operation

Offers flexible operational modes for varied applications.

High-Speed Operation with Controlled Tension

Maintains high speeds while accurately controlling tension.

Programmable Operations

All Windak rewind lines are equipped with the ability to run to a set length at a predetermined speed.

Semi-Automatic Reel Unloading Cycle

Includes a feature where the reel descends and the pintles open up around it for easy unloading.

Compatible Equipment

Accumulators

Windak Group specializes in both vertical and horizontal accumulator designs, providing versatile solutions for various production lines.

Dancers

Windak Group has a rich history of developing, constructing, and supplying a diverse range of dancers- gravity, pneumatic and servo driven types.

Length Counters

Windak length counters are equipped with adjustable horizontal and vertical guide rollers, ensuring precise measurements.

Reel Inline Packaging System

Windak’s Change-Over stations are used for INLINE operation, allowing continuous production on the extrusion line.

Additional Equipment

Our advanced technology ensures seamless quality control in unmanned, fully automatic operations.